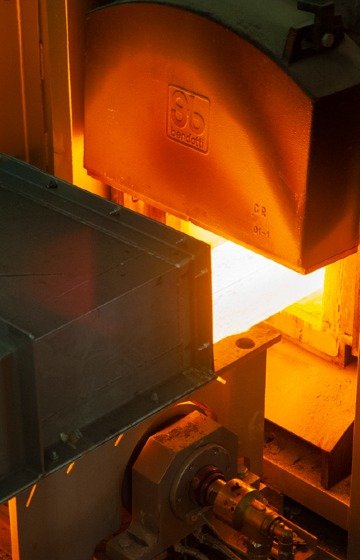

Founded in 1933, today O.R.I. Martin S.p.A is a modern electric furnace steel mill that produces special steels for various applications, mainly in the automotive sector (bolts, suspension springs, torsion bars, steering and transmission components), mechanics, energy and construction.

Its Brescia site produces continuous casting billets, hot rolled steel in coils and bars, and induction tempered wire.

The company is also equipped with modern systems for the annealing and quenching and tempering of bars and coils and at Trafilati Martin Spa, with systems for the chemical pickling and sandblasting of coils.

Products

- All

- Wire rod

- Hot rolled bars

- Induction tempered wire

- Continuous casting billets

- Hot rolled round bars

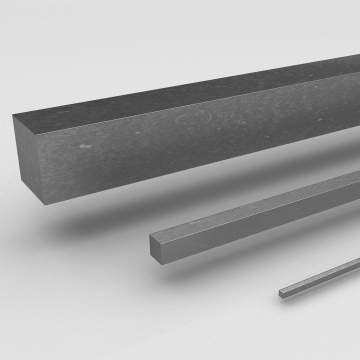

- Hot rolled square bars

- Hot rolled flat bars

- Hot rolled billets

Products

Production process

Sales

Sales

team members